中/EN

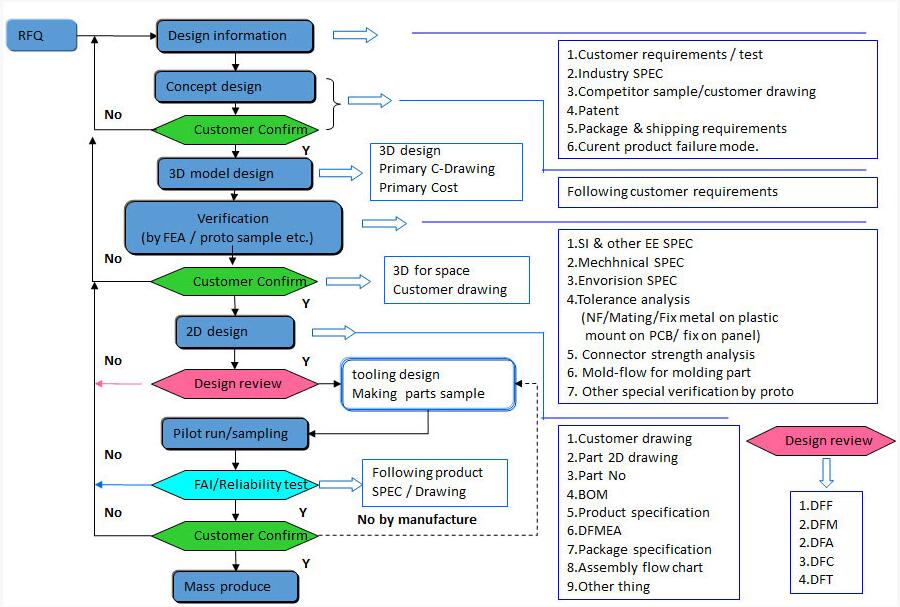

In order to ensure the timeliness, quality of product development, the company has established a perfect product development process, the product design from the beginning to import, product design verification, complete the whole process of production are in control, so as to meet customer requirements of product performance, reduce manufacturing cost, ensure the quality of products, shorten the product development cycle, lay the flow of the necessary foundation.

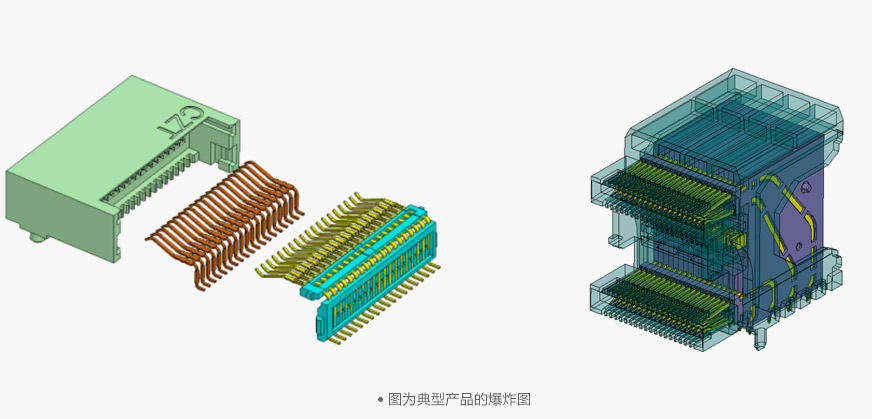

Each R & D team has the R & D capability and CAD capability of its own division of responsibility products, and continuously develops, maintains and develops new products according to the company's strategic intent and established product roadmap.

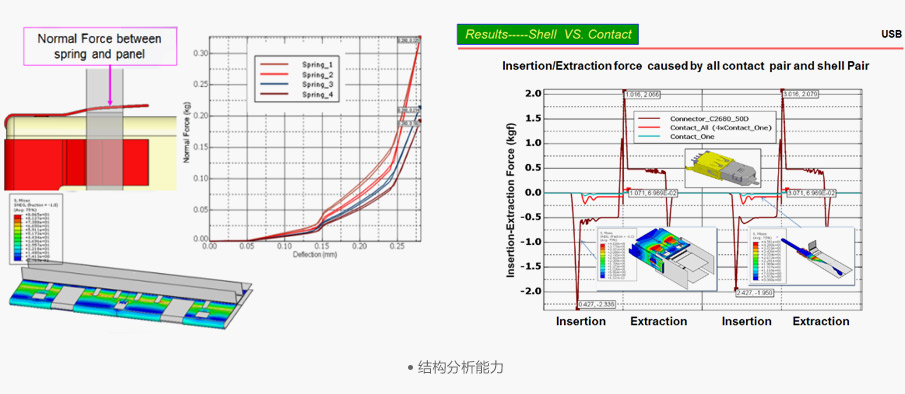

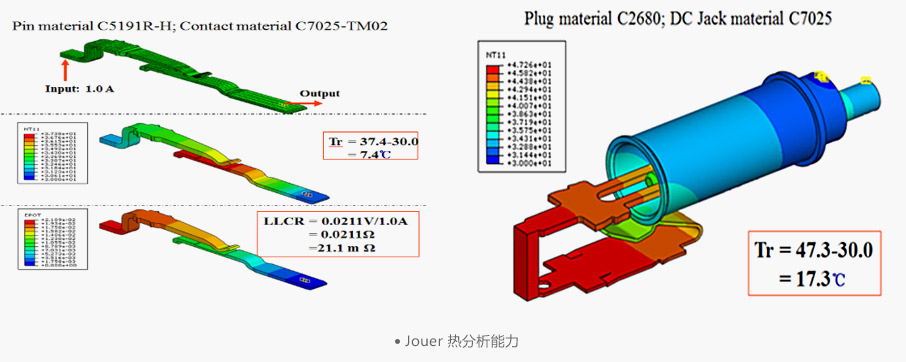

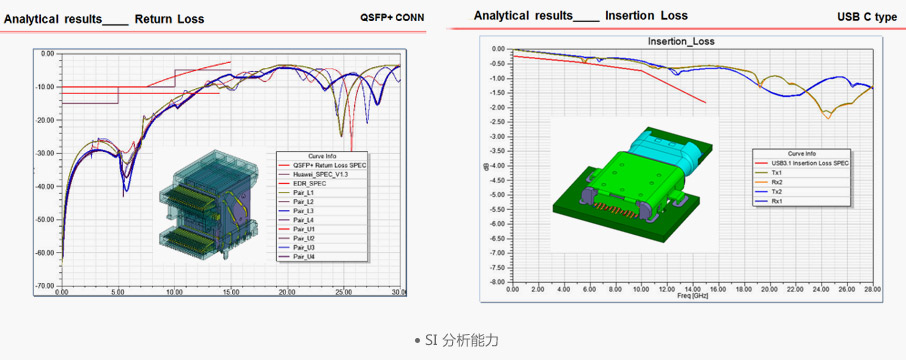

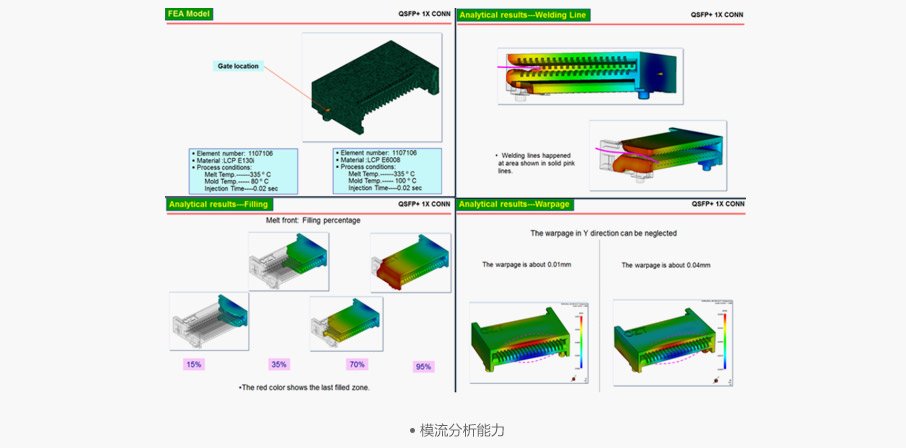

The company has the CAE engineering analysis capability of connector development, such as structural analysis, die flow analysis, signal integrity analysis, thermal analysis, etc.. In the product development process, we can determine the product performance, product manufacturing and so on. So as to save product R & D cost, shorten product research and development cycle, and improve product design quality.

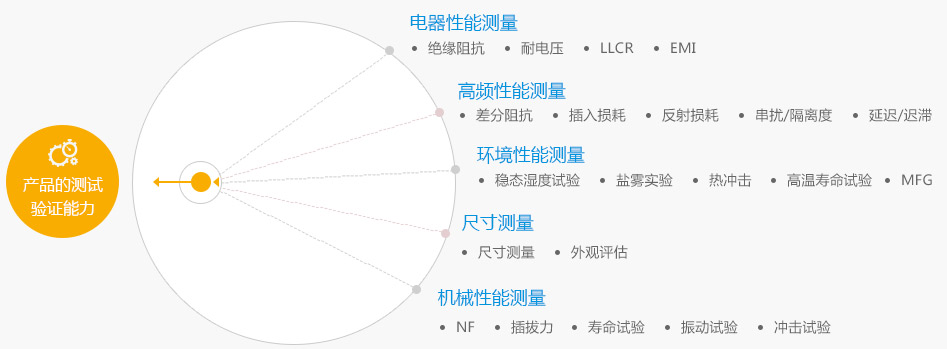

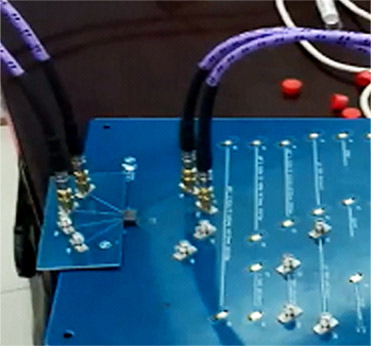

The company has the ability to improve the product verification test specification, the R & D team, according to industry standards, customer requirements, mechanical properties, electrical properties of the product, environmental performance, signal integrity performance test. Ensure the reliability of the product.

Tel: 0086-577-62811899 ![]()

Add: Block K, Wengyang Industrial Zone, Yueqing City, Zhejiang,P.R.China![]()